Heat Treating Furnace – Our Heat Treating Furnace is specifically designated for Beryllium Copper. Through Research and Development with Our Customer we have been able to Heat Treat various Beryllium Copper parts to the Print Specified Rockwell Hardness and with no Scale, leaving a bright, smooth finish.

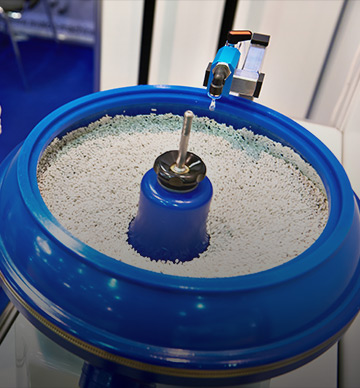

Polishing Machines – We have three Polishing Machines that provide Vibratory Tumbling. Vibratory Tumbling is effective for creating smooth and polished surfaces on specific parts that require a Micro-Finish that we are unable to establish through our machining process. Our form of polishing is very effective in providing incredible smooth surfaces on even the most fragile metal parts. We combine specialized media, abrasive, and solution with water to the polisher, along with the parts. The vibration promotes a powerful collision between the parts, water, abrasive, and media, along with designated run time to create the finish specification for the part.

Tool Room – Our Expert Toolmakers within our Tool Room Facilities provide Secondary Grinding, Hole Drilling, and Bias Cuts for providing a finished part that meets our customer’s needs.